We’ve come a long way here at ID Integration since our start 20 years ago. Back then, we borrowed the technology used for tracking pets with microchips and applied it to RFID tracking for structural aerospace parts. By 2003, we spearheaded the development of UID MIL-STD-130 policy and continue to support IUID integration implementation today. Our clients see a return on their investments when identifying parts, assets, and tools using the newest RFID technology, barcode technology, cloud software, and more.

Barcode and RFID hybrid tech, used in combination, is the hot new trend in smart manufacturing for improving production efficiency and work in process (WIP) visibility. Many defense industry manufacturers are already riding this new wave of technology by tagging some parts with IUID tags and others with RFID tags. But the question remains: Can these technological breakthroughs work together seamlessly without the headaches of juggling disparate data? The answer is YES!

Here at ID Integration, we continuously expand our capabilities to include next-generation technology that provides a complete range of very affordable and innovative solutions to integrate these separate tracking methods together. We make it possible to use compliant MIL-STD-130 marks in combination with advanced RFID technology, to enhance WIP and overall production insight. Even in circumstances where legacy MIL-STD-130 software is in use, we offer many modern solutions to bridge the integration gap to fit your budget.

Our technologies have multiple applications—In addition to production analysis and process improvement, you’ll find audits easier.

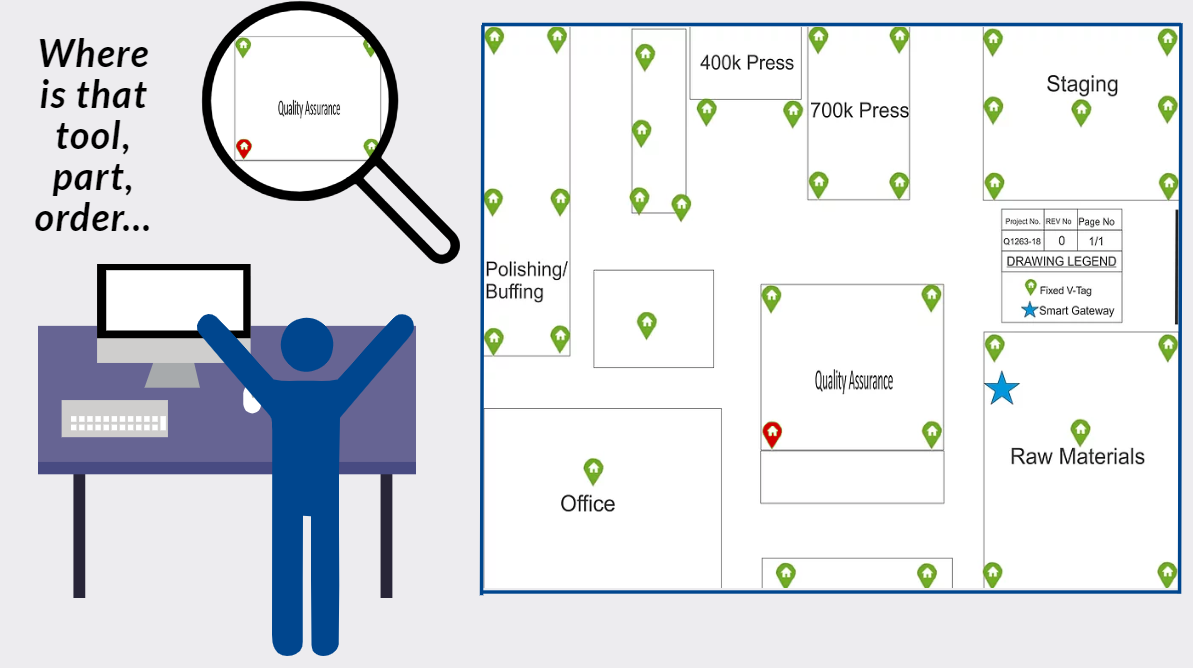

Simply locate expensive parts and keep track of tooling by viewing them on a software map of your warehouse facility.

Learn about our catalog of cutting-edge barcoding technology and RFID technology for smart manufacturing and asset tracking.

![]()

Explore our new and timeless resources for MIL-STD-130 compliance:

- Barcoding 101—Start with labeling and nameplate specifications and requirements for meeting MIL-STD-130 standards. Then, discover the variety of options available for IUID direct part marking (DPM) to suit the size and material of the part to be marked. We offer marking hardware, software, scanners, and verification systems to work in tandem.

- Cut Costs and Improve Compliance with Intelligent IUID Scanners—Our experts designed our BarCodeOS ® enabled scanners to eliminate the need of downloading expensive middleware to handle outmoded software. Read raw data of the IUID Data Matrix mark, parse IUID data, and conduct data validation and error reporting with an auditory “one beep is good and 4 beeps is bad” signal. During scanning, your system remains safe with the World’s ONLY Barcode scanning software equipped with firewall protection.

- Add RFID Location Tracking for Cost-Efficient Tool Tracking & More—Forget about building in expensive infrastructure and antennae when locating assets. With our V-Tag™ Active RFID Tag System, you’ll enter the world of smart technology. Each tags “talks” with each other by creating a mesh network to enable tracking on demand at just half the price of traditional passive RFID systems. The V-Tag™ system keeps track of your assets, and coupled with AssetWorx!™ RFID software, view locations in real-time on a software map of your facility. Gone are the time-consuming headaches of audits with on-demand asset tracking. Do you need to track assets outdoors? Learn more about today’s innovative V-Tag GPS™ RFID tracking system and learn how to track and activate using your smartphone or tablet.

- Jump on Cloud Technology for the Benefits Offered by the Internet of Things (IoT)— The first IoT RFID reader is here, an inexpensive workhorse that plugs into a standard wall socket to tap into the cloud. With the Brady© CenSys RFID Reader, building expensive infrastructure is a thing of the past. Track tagged assets while on the go with a laptop, tablet, and smartphone. Or consider the benefits of a newer solution, Xemelgo X track, also compatible with the new CenSys RFID Reader. This unique solution delivers Industry 4.0 tech to manufacturing – incorporating IoT, Cloud, Mobile, and AI using a Google Maps-style software approach. You’ll gain more than visibility and efficiency while experiencing a smart manufacturing solution that enables real-time data-driven intel throughout your entire manufacturing and production process.

- Integrate Existing and New Asset Tracking Methods—That’s what our IUID compliancy team experts have been doing for more than 20 years. Contact us for individualized consulting services at 425-438-2533. We protect your bottom line by working with your existing systems instead of overhauling your present technology and forcing you to start from scratch. See how to blend the old with the new for a customized asset tracking system that fits your specific needs for WIP efficiency, tool tracking, expiring chemicals management, & more!

Explore our resources to further help you meet the needs of MIL-STD-130 compliance & understand general asset tracking benefits:

Get the FAQs—Your frequently asked questions are answered by the ID Integration compliancy experts

Read our white papers

“Avoiding the Expense of RFID Asset Tracking Infrastructures”

“Easy IUID Audit Prep with High Tech BarCodeOS ® Scanners”

“Is a Barcode Security Threat Looming in Your Company’s Future?”

“Leveraging IoT and Cloud Manufacturing to Revolutionize Asset Tracking & Audit Prep”

“The Holistic View of RFID Location Tracking”

View our articles:

“ID Integration Using Technology to Help Companies Keep Track of Stuff”

Download the Podcast: