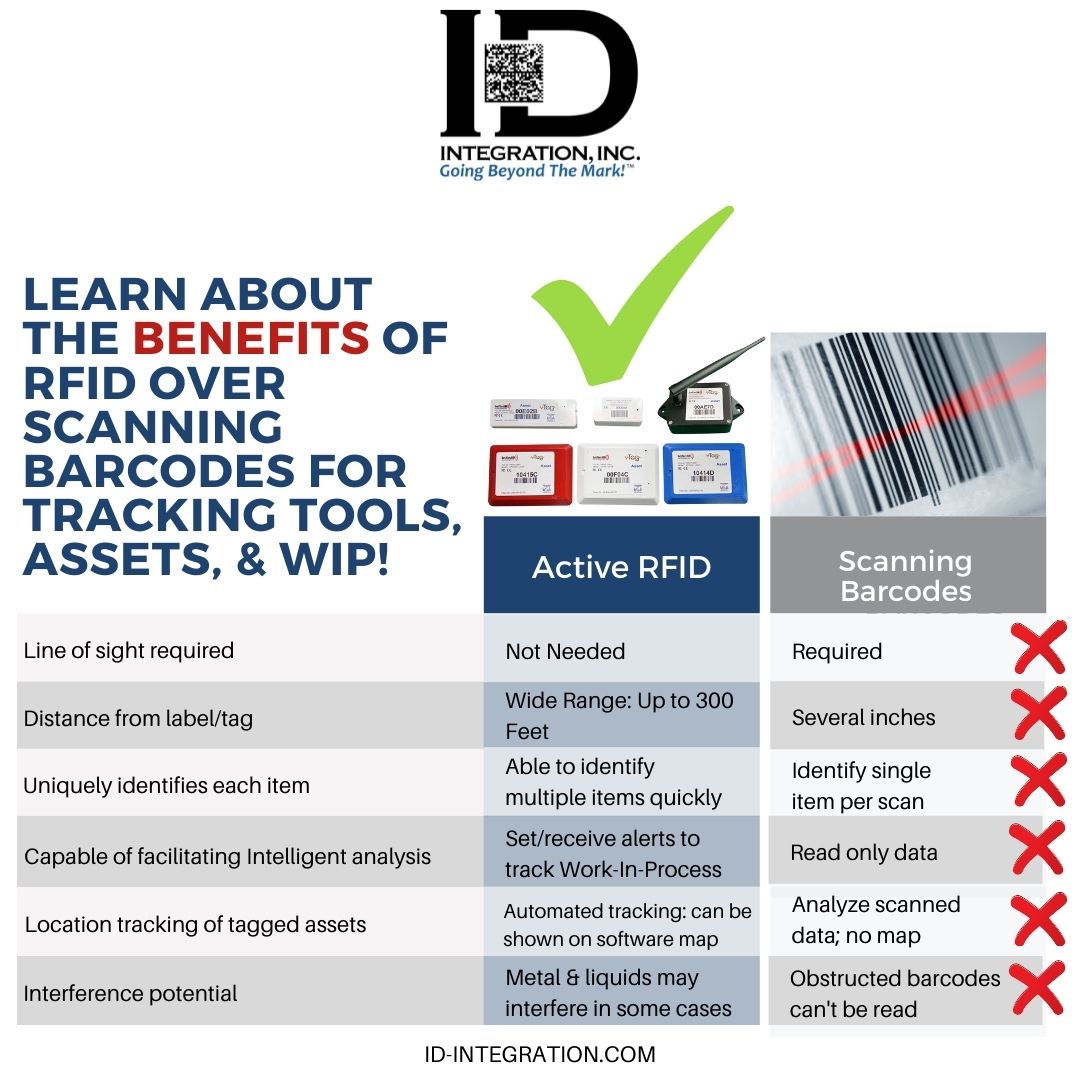

The difference between tracking tools and assets, expiring chemicals, and hazardous materials by hand vs. with RFID is like the difference between night and day. Human errors create unnecessary expenditures in labor costs and the cost of rectifying mistakes. When accuracy comes into question, efficiency is compromised.

Barcode technology has its limits: When each barcode must be in line-of-sight for a scanner to read, logging in assets becomes a chore. Here at ID Integration, we’ve tested the most reliable RFID solutions to locating tools, jigs, and fixtures in plants, warehouses, between buildings, and shipyards. Our active RFID solutions make quick work of measuring expiration dates of chemicals, viewing inventory for audit preparation, and keeping track of tools for keeping up on compliance standards. Manage WIP (work-in-progress) across your manufacturing floor effortlessly.

We have the ultimate RFID solution: V-Tag™ technology. Read our free paper “Avoiding the Expense of RFID Asset Tracking Infrastructures” and discover how V-Tags™

• Eliminate the need to buy and configure expensive antennas and infrastructures.

Active V-Tag™ RFID tags actually “talk” to each other by forming an ad hoc mesh network that relays info between tags. Forget about installing network cables, too. Even software licensing is unnecessary. This easy-to-install system costs almost 50% less than passive systems.

• Eliminate excessive labor costs getting set up and running.

V-Tag™ tech is easy to set up and easy to use. Scan multiple tags at once, instead of wasting time scanning each label. Then, simply type in an asset’s name and it appears in real-time on a software map of your office building, warehouse, or job site. Set up parameters to measure movement, temperature, and battery levels, and be alerted when items are moved, storage temps fluctuate, and tag batteries run low. Know definitively whether hazardous chemicals are mishandled and where WIP is stalled.

V-Tag™ Active RFID Tags are designed for indoor use, and V-Tag™ GPS Long-Range tags are designed for the rugged outdoors. Mix and match to customize for your needs.

V-Tags™ also come in an assortment of sizes and shapes to fit your applications, from the classic V-Tag™ active RFID tag that’s just the size of a box of Tic Tacs, to a V-Tag™ barely larger than a quarter, to a V-Tag™ the length of a stick of gum, to a V-Tag™ created to attach to your laptop and important documents.

Read how V-Tags™ can amp up your efficiency exponentially. Download our free guide “Lean Manufacturing For Tool Tracking & Chemical Inventory Management” to find out how V-Tag™ technology revolutionizes chemical inventory efficiency, chemical quality and safety, label durability, and proper tool calibration.

Contact us for a live online demo to witness how to put V-Tags™ to work for your company. Our RFID experts are available to problem-solve your specific roadblocks to efficiency. Give us a call at (425) 438-2533 for budget-friendly RFID technology recommendations.