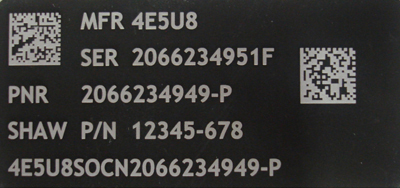

IUID Labels

Compliant IUID Labels Start with State-of-the-Art Marking Hardware

Meeting the MIL-STD-130 labeling specifications requires hardware solutions that are not only DoD compliant—They also must withstand the test of time. Life cycle management and tracking of assets need to measure up to government standards. This starts with selecting the best hardware for delivering compliant MIL-STD-130 IUID labels. Below are a few hardware solutions to consider.

Let’s begin with IUID laser printers, which can provide marking directly on parts of various materials. Thermal label printers are also used for IUID marking and differ from IUID laser printers in that they produce labels that meet government standards, instead of marking directly on a part. When thermal label printers are RFID enabled, they can print the 2D Data Matrix codes along with the encoded RFID tag that improves asset tracking. CO2 laser systems also produce MIL-STD-130 labels that can be applied directly to military property.

Laser polymer bond marking creates marks that can be applied directly to metals, ceramics, and glass, in addition to IUID labels. With this method, the lasers actually fuse the material to the substrate to create chemically resistant marks that can withstand high temperatures, moisture, salt water, and abrasions. High-resolution ink stencils are another choice for marking hardware, particularly directly onto metal.

Dot peen systems also create indelible marks directly onto the part, and this method is particularly suitable for varying item sizes. This system is also suitable for marking a number of different materials, including aluminum and mild steel. Dot peen marking works differently than laser and polymer bond marking: dots are indented into parts, resulting in machine-readable and human-readable text that complies with DoD IUID requirements.

Many parts manufacturers prefer automated chemical etching systems for marking directly onto a part, because of the high resolution that can be achieved. This chemical etching equipment includes a stencil with a marking unit, and an electrolyte, to produce numbers on a plate.

Whichever hardware you choose, it must be integrated with software, scanners, verification systems, and registration to be compliant with the MIL-STD-130 requirements. Here at ID Integration, Inc., we streamline this process of compliancy with the best solutions for your company. Contact us today.