MIL-STD-130 Marking Hardware Solutions: Laser Marking System

IUID compliance requires contractors to the United States Department of Defense to meet strident standards that include proper MIL-STD-130 marking. Marking can only be achieved through approved methods and hardware solutions that utilize 2D Data Matrix encoding that provide fluid item management and asset visibility among other benefits. Regardless of the hardware or method, markings must be durable and endure the life span of the item while being exposed to harsh conditions, including extreme weather and chemical exposure.

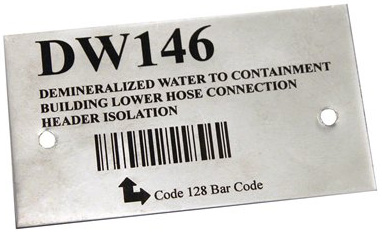

Among the varied approved hardware is IUID Laser Marking Systems that are able to provide direct part marking for items that will become property of the United States Department of Defense (DoD). This type of hardware provides solutions for contractors and manufacturers of the government in order to more efficiently meet IUID integration and compliance standards. An IUID Laser Printer has the ability to support various materials and provides comprehensive solutions, including production of labelsCutting materials are varied, but only approved materials should be used in order to meet compliance standards, such as anodized aluminum, tesa and 3M laser markable tapes.

IUID Laser Printers provide direct part marking that is a non-contact thermal process. An IUID Laser Printer will produce IUID compliant Data Matrix marks that provide manufacturers and the DoD more accurate and reliable asset tracking, as well as inventory control and unfailing traceability.

CO2 marking lasers will produce high quality IUID labels that will meet MIL-STD-130 marking regulations. ID Integration, Inc. can provide more guidance for customers in need of approved marking hardware solutions, as well as software solutions, scanners, verification systems and registration.

IUID compliance can be improved with guidance from ID Integration, Inc. ID Integration works with approved vendors for improved compliance and production of labels, nameplates or tags, as well as direct part marking. These labels will improve workflow within the manufacturer’s company in addition to improved asset management and visibility that is crucial to the IUID process as designated by the DoD.