FDA UDI FAQs - Answers to Your Frequently Asked Questions

To understand what it takes to follow the most recent FDA UDI regulations, our experts compiled answers to your most frequently asked questions.

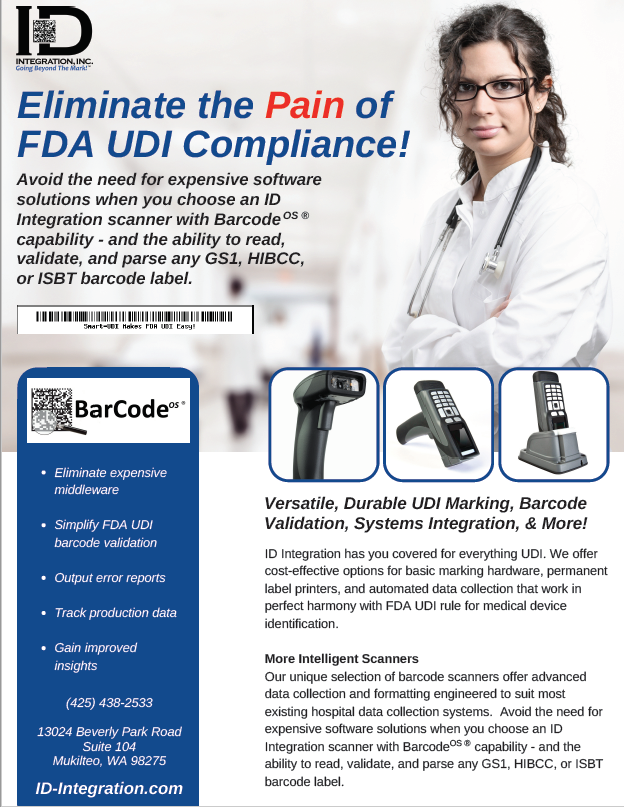

Although ‘verification’ camera systems exist for FDA compliance testing, they are expensive and NOT portable. In contrast, our family of BarCodeOS ® enabled scanners provides real-time validation of all GS1, HIBCC, and ISBT Blood Bank barcodes. One Beep = VALID; Four Beeps = INVALID. Error reporting is a user-selectable option.

BarCodeOS enabled scanners make validation of FDA markings easy:

✓ No PC Driver or software requirements – plug in the USB cable to create ‘keyboard #2’ for your PC.

✓ Works out of the box, but is custom configurable via any browser enabled device – just scan off the screen.

✓ Smart-UDI offers validation and parsing capabilities that are in line for with the final FDA UDI ruling and for submission to the Global Unique Device Identification Database (GUDID)

✓ Simple auditory signals make for quick validation—One beep means the barcode is good and in FDA compliance, and four beeps means it’s bad

BarCodeOS Scanners are the affordable UDI scanner software solution:

✓ Minimize labor costs with speedy determination of whether a barcode meets FDA requirements or not

✓ Fast, easy, and secure configuration can eliminate the need for IT support

✓ As the World’s only barcode reader software equipped with a FIREWALL, you’ll avoid malicious operating system attacks which can be embedded in 2D barcodes.

Watch our YouTube video to see the ease of BarCodeOS technology.

Our FDA experts customize BarCodeOS enabled scanners to fit your specific needs. Reach them for at 425-438-2533 for a no obligation consultation.

The FDA insists that all UDI marks last the lifetime of the product. To comply, we present a variety of marking hardware methods to choose from, depending upon the size of the part and the material that is to be marked.

Rely on Direct Part Marking (DPM) when traceability is necessary if the part is separated from its packaging and when the part is too small to be affixed with a barcode label or tag.

CO2 Laser Marking Systems

This is possibly the universally best way to mark most items. Lasers are available in various powers and strengths. Laser etching and engraving removes material from the surface to create the mark. To avoid an impression on the surface, laser annealing is possible on ferrous materials containing iron—It draws carbon to the surface to create a dark mark that is permanent. Laser marking is also available for plastics, where the laser discolors the material to create the mark.

Laser Polymer Bond Marking

Instead of etching into the part, a material, such as CerMark laser bonding material, is placed on the surface of the part. When it is lased, the material fuses to the part, creating a permanent, non-intrusive mark. These marks are ideal for producing high contrast, chemically resistant, heat resistant, and moisture resistant identifications. Laser polymer bond marking is also used on labels that are permanently affixed to parts and products.

Automated Electro-Chemical Etching

This older technology is still in use today for medical device labeling. It is more time consuming than laser methods and is a less expensive alternative for low-volume industries.

Watch our video demonstration of Direct Part Marking from the UDI Conference 2016 for more details. Then see how easy they are to read.

Consider creating labels that display indelible information that is permanently attached to larger devices:

Thermal Label Printer Systems

Print permanent 2D Data Matrix codes and RFID labels in accordance with FDA requirements. See our video of label inkjet marking in action.

Laser Printer Systems

Use a non-contact thermal process to create labels, nameplates, and tags that last the test of time.

Contact us for assistance determining which marking system is best for your parts—Call 425-438-2533.

Here at ID Integration, we recommend only FDA-approved software: BarTender Label Design Software from Seagull Scientific. Create, print, and automate the manufacturing of RFID tags and UDI labels that are affixed to the surface of devices. Expect error-free production to streamline your workflow. These labels withstand harsh environmental conditions to ensure readability for the life of the product.

To prevent the incidences of malware attacks from malicious operating commends lurking within Data Matrix, QR, and PDF417 barcodes, we developed the World’s Only patented barcode filter software that serves as a FIREWALL.

Our exclusive BarCodeOS ® enabled scanners protect PCs from OS attacks, effectively nullifying their impact and identifying the codes having an eventually harmful intent.

The Final Rule for FDA Unique Device Identification declares that the UDI is required directly on a device itself when the device is to be used more than once and reprocessed (disinfected, or sterilized, for instance) before each use. Specifics for this direct marking rule stipulates:

✓ The mark must be easily readable text

✓ Automatic Identification and Capture (AIDC) technology must be used to provide the UDI of a device on demand

Read more specifics on the FDA code for direct marking of devices, including exceptions to the direct marking requirement.

FDA labeling requirements for packaging are more complicated. A device package contains a “fixed quantity of a unique version or model of a device”. The Device Identifier (DI) is on the label for the device itself. It also includes Production Identifiers (PIs), including serial numbers, dates of manufacture and expiration, lot number, and more. The simplest example is when just one device is enclosed within a package, and this package is called the “base package”. The UDI on the device contains the DI and the PI, along with the correct date formats and more information.

When a number of devices are included in a package, that package uses a different device identifier (DI). In other words, the FDA requires a unique UDI for each product, and a box of 12 of those products would then need a different UDI, and a case of 24 of those boxes would need yet another UDI.

Here at ID Integration, we help clients sort out these FDA device identification requirements. Contact us at 425-438-2533 to ensure that your individual units and packages are labeled correctly for submission to the GUDID.

You could sift through the specific FDA General Device Labeling Requirements, General Device Labeling Provisions, the entire gamut of Federal Regulations for Electronic Codes, and the FDA Final Rule on Unique Device Identification, but how will you know if you’ve interpreted the regulations correctly? And furthermore, how can you confirm that you aren’t spending more money than necessary to comply?

That’s where our UDI team comes in. Our experienced UDI integrators are available to assess your parts and devices and recommend the most appropriate, cost-saving solutions to fit your needs while meeting the FDA requirements. Whether you need approved 2D Data Matrix label hardware or software, hand-held 2D Data Matrix scanners, and our BarCodeOS Software Suite for validation of your GS1 2D Data Matrix codes, we’ve got you covered.

Our solutions are customized, creating the most affordable solutions for FDA compliance. We never convince you to buy what you don’t need, because we want to remain on your speed dial for all your compliancy needs.

To accomplish this, we run a complete needs assessment, and we get back to you with our recommendations. We don’t stop there—We are here to assist you through purchase, installation, training, and maintenance. ID Integration is your one-stop shop for all of your FDA compliance needs. Get started by contacting us at 425-438-2533 for a no obligation assessment.

No. Not every medical device needs to be labeled. To understand the exemptions, it is first important to know the definition of each distinct class of medical device, as defined by the FDA:

Class I Devices—These items have the least regulatory controls, because they are deemed to be of low risk. Examples include gauze bandages and dental floss.

Class II Devices—These items require more regulatory controls than Class I Devices, because they carry a higher risk of usage. This increase in controls provides increased assurance of safety and effectiveness. Surgical instruments and ultrasound scanners are examples of Class II Devices.

Class III Devices—These items carry the highest risk of usage and must be approved by the FDA before they are marketed. Examples include implantable devices, such as replacement heart valves.

The FDA lists exemptions according to Class:

Class I Devices do not need to include Production Identifiers (PIs) within the UDI. The UDI only needs to contain a Device Identifier (DI).

Some Class I and Class II Devices are completely exempt under the Good Manufacturing Practice (GMP) Quality System exemptions. Visit the FDA website for a specific list of these items.

All packaged Single Use Devices (SUDs) are not required to carry a UDI on the device itself. However, the UDI is required to be printed on the outside of the multi-pack.

Implantable medical devices do not need to carry a UDI on the device itself, but the UDI is required on their packaging.

If a Class I Device is labeled with a Universal Product Code (UPC) number, then this number can take the place of a UDI on both the device and its packaging. However, both the UPC and a UDI are required on the device label and the highest level of packaging.

Products that carry a National Drug Code (NDC) can use this number as the UDI number on the highest level of packaging.

Additionally, an exemption to the FDA Direct Marking Requirement is granted when:

Direct marking interferes with the safety and effectiveness of the device

Direct marking is not technologically viable

The device has been marked previously

The device is a reprocessed device for single use

When a device cannot be marked, this information must be noted in the design history of the device.

The FDA takes note of mismarking devices and their packaging because such noncompliance can cause significant health threats. To ensure that your devices and packages are marked correctly, consult with a UDI Integrator with experience—Here at ID Integration, our staff of experts guide you through the entire FDA UDI process. Get started today—Reach us at 425-438-2533.

Each Unique Device Identifier (UDI) contains two parts, the Device Identifier (DI) and the Production Identifier (PI):

Coding requirements for the DI:

Static data includes manufacturer, make and model

Globally unique product code

Particular product attributes

Synchronization to the GUDID (the Global Unique Device Identification Database)

Coding requirements for the PI:

Dynamic data that includes serial and/or lot number, expiration date, and additional manufacturing data

This code is unique for each product

This code is required on all levels of packaging

To confirm that your UDIs follow the proper FDA nomenclature, get feedback from our team. We’re here to help: 425-438-2533.

ID Integration is a seasoned systems integrator with the ability to facilitate UDI compliance from every aspect—From marking individual parts to validating identifications, to helping you integrate the data between existing and new database systems, to enterprise software, to so much more.

Our technologies were first tested and accepted for marking and labeling equipment for the Department of Defense and military applications. Our approved methods are considered the standard for identification and validation of parts tracked by the government. We now offer these technologies to complete FDA UDI compliance seamlessly.

Schedule an assessment of your marking and validation processes, and we’ll interpret the complex FDA UDI Final Rule for you and determine the most cost-efficient means for your devices to pass compliancy. It just takes a phone call: 425-438-2533.

AIDC stands for Automatic Identification and Data Capture, and it is the method used to automatically identify objects, capture data about them, and enter that data within databases without relying on humans to physically accomplish this.

Entering repetitive data, such as FDA UDIs, can be fraught with errors when humans are given this task, but machine entry is not prone to this fatigue factor and accomplishes data entry much faster. Therefore, the initial expenditure in technology is offset in the savings in labor.

Here at ID Integration, our BarCodeOS ® enabled scanners enable your barcode readers to scan without the need for human interpretation. Validation is simplified, with an audible single beep that means a UDI is good, and 4 beeps indicate a device is mislabeled. This eliminates human errors and allows for quick submission into the GUDID.

ID Integration is the only UDI systems integrator that offers the BarCodeOS enabled scanners. Discover how this technology can be customized for your specific needs. Contact us at 425-438-2533.