ID Integration Celebrates Continued Support for U.S. Army CH-47 PMO After Successful Decade of IUID Project

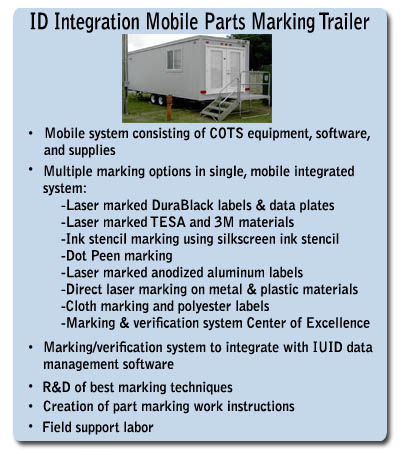

For a mobile marking solution to really work, it must be adaptable to a variety of marking application challenges. Such a successful solution is IUID Marking Technologies in Mobile Marking Trailercapable of marking, scanning/verifying, and capturing data for a wide range of substrate materials, while able to withstand harsh environmental conditions and maintain compatibility with the numerous sizes and shapes of all new and used parts included in today’s U.S. Army CH-47 PMO project.

The initial ID Integration mobile marking trailers have proven to be extremely useful to the entire range of on-base challenges presented as commonplace hurdles. In addition to the overall success of the Chinook parts marking initiative, these trailers have become core components of the CH-47 PMO program – ensuring streamlined data collection, flexible marking, and quality verification with full support for in-the-field application. In short, ID Integration’s mobile marking trailers have delivered a flexible means of continuously achieving compliance with stringent Department of Defense guidelines for all emerging IUID requirements.

What makes this solution so beneficial is its ability to provide compliant nameplates and tags, or even direct part marks, on a wide range of substrate materials and direct parts for continuous tracking throughout the complete maintenance and distribution life cycle for their use within the field. Both new and used parts can efficiently be marked as required and the implementation of this project has also provided an answer to updating some of the Army’s older parts, now possessing degrading identification due to the natural wear and tear of parts put through the tests of harsh environmental and usage conditions.

Inside each mobile marking trailer, operators have access to a comprehensive array of marking, data capture, scanning, and verification equipment ID Integration IUID mobile marking trailer able to integrate with current IUID data management software. “The trailers Boeing purchased from us became centers of excellence,” said Gary

Moe, President of ID Integration. “They could test various labeling methods. And it all got its start from meetings with Dennis Priddy, the inventor of Data Matrix code.”

The CH-47 program evolved with the development of custom software applications and barcode scanner applications that enabled collection of legacy IUID data and UID registration. One example of such innovative and useful technology, is evidenced in a challenge where field teams gained the ability to photograph legacy Chinook parts to catalog by helicopter tail number in a secure, web-based application. Their ease of detailed cataloging was made possible through a number of additional features derived from the development of unique barcode scanning software solutions.

From the start of involvement with ID Integration’s first contract from Boeing Philadelphia to a full decade of innovation and support, these IUID mobile parts marking trailers quickly became a deployable solution with the flexibility to overcome nearly all Department of Defense compliance identification tests. Today, all field technicians are experienced CH-47 maintenance personnel, in addition to the unique qualifications and experience working within Opportunistic Parts Marking performance. The CH-47 program continues to work with great success as ID Integration continues to support the U.S. Army with their efforts to meet IUID marking requirements per the DoD’s standards.