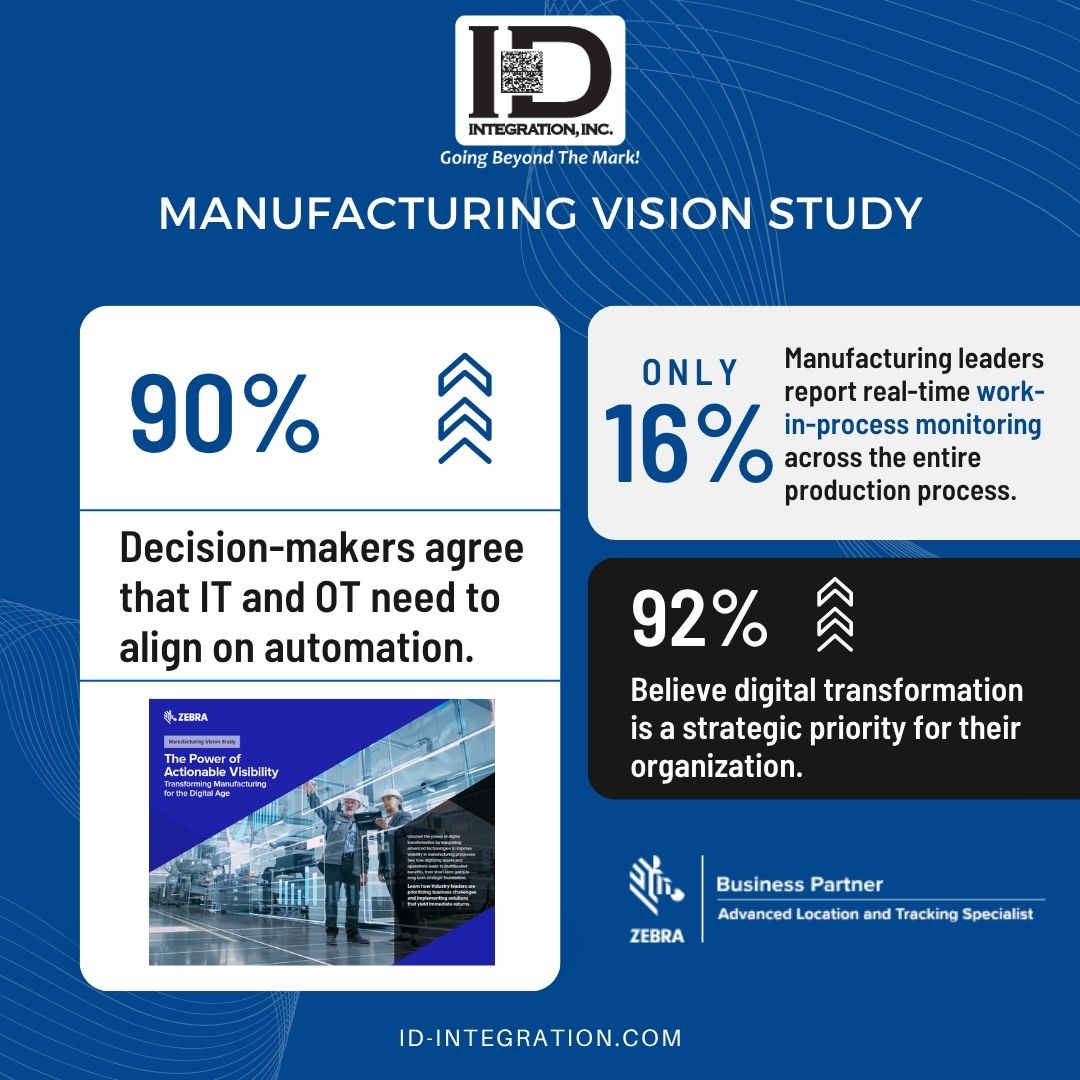

Most plants still lose time looking for the right tool, bin, or fixture. Zebra’s latest Manufacturing Vision Study reports that only 16% of manufacturers have real-time visibility into work-in-process across their entire production line. That gap shows up as delays, rework, and avoidable downtime.

This is not a recap. It is a practical plan that you can run while sharing the study with your team.

What we see on the floor

•Data exists but arrives late or lives in separate systems.

•Barcode counts help accuracy, but not recovery when items go missing.

•Teams want visibility without extra operator steps.

A workable pattern with passive RFID

Use passive RFID so movements are captured automatically. Read many items at once without line of sight. Place fixed readers at the crib window, bay door, or gate between cells. Keep handhelds for spot checks and audits. Write events into the systems supervisors already use.

What improves first:

- Find time: last-seen location reduces search.

- Counts: faster cycle counts surface shelf-life issues earlier.

- Calibration: intervals stay on track for critical tools.

Try this in the next 30 days

• Pick one gate: a crib window, receiving door, or a WIP checkpoint that slows you down today.

• Tag priority items: tools, bins, or assemblies that are frequently chased.

• Stand up one read zone: confirm movements appear without extra operator steps.

• Add a handheld: close the loop quickly when something is out of place.

• Put data where people look: feed events to ERP or MES; start with a simple board showing last-seen and in-route.

• Review together: IT and operations align on results, security, and next moves.

Measure progress without boiling the ocean

• Median time to find a missing tool or container

• First-pass yield on cycle counts for parts and chemicals

• Number of past-due calibration items

• Unplanned holds tied to missing assets

If the trend lines improve, expand to a second gate. If not, adjust the read zone and retry.

Read the Manufacturing Vision Study

Zebra’s Manufacturing Vision Study reinforces the same themes: real-time status, aligned teams, and practical pilots. Download the full study here.

Put it to work

ID Integration supports the full journey: discovery, solution design, reader and tag selection, systems integration, validation, training, and ongoing support. We help teams scale from a first deployment to network-wide standards with security, audit trails, and measurable results. Reach out to schedule an online or in-person demo by calling (425) 438-2533.

Looking for more educational resources? Visit our updated resources page for FAQs, videos, and more.